How To Remove Jb Weld From Pipe

When fully cured J-B Weld can only be removed by grinding or filing it off or by directly heating the product above the 600 degree maximum temperature threshold. Theres adhesives available from a company called Loctite that come in different formulas.

Is Jb Weld Strong Enough To Repair A Broken Connecting Rod Let S Find Out Youtube

Clean surface removing any dirt or debris.

How to remove jb weld from pipe. By this point in the process the JB Weld had hardened. With black pipe I would clean the threads really well to remove cutting-fluid used by the factory. FiberWeld Pipe Repair Cast is a high strength fiberglass wrap impregnated with a specially-formulated resin to repair pipes up to 1-in in diameter.

This seal is extremely temporary however as electricians tape is not waterproof. I know this because I had to look it up last summer. Knead WaterWeld with your fingers until it becomes a uniform color and apply along the line of the crack.

When fully cured J-B Weld can only be removed by grinding or filing it off or by directly heating the product above the 600º maximum temperature threshold. It was time to smooth out the inside of the bowl and remove the excess JB Weld. In my experience hot coolant in a radiater will eat through JB Weld on a seam.

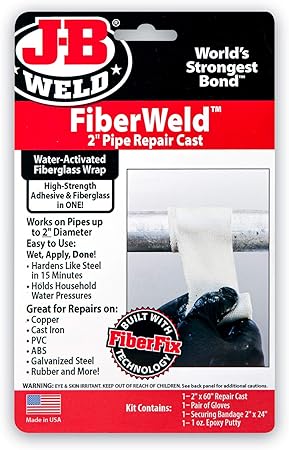

I think a JB Weld or brazing job could be done but it would not be a permanent repair at any rate. How to Fix a Water Leak in a Pipe With JB Weld or Plumbers Epoxy Putty. JB Weld Brand J-B Weld Model FIBERWELD 2x60 PIPE REPAIR CAST WHITE Item Weight 352 ounces Product Dimensions 15 x 494 x 787 inches Item model number 38260 Manufacturer Part Number 38260 Cover Included Roll of Repair Tape.

Use a tool like an angle grinder a Dremel and sandpaper to completely remove JB Weld. When grinding please make sure to wear a mask or respirator to avoid inhaling the dust because it. If you are thinking of doing this in-car you should know that it is exceptionally easy to remove this pipe.

I used the Dremel with a sanding drum to smooth out the back side of the bowl. If its on metal you can usually remove it by getting underneath of it with an X-acto knife. This method can be hard but sure will work.

Additionally can you use JB Weld on copper pipe. At least two different brands on the market -- JB Weld and Harveys Epoxy Putty -- work equally well for the purposes of stopping leaks. Second application fixed the leak for now.

It had been about 4-5 hours. The JB weld held for about 3 days the low temp silver bearing solder held for at least 4 years. You can but JB Weld is an epoxy so getting the surface clean enough and slight scuffed is required for the epoxy to stick.

There is one 10mm bolt holding it by a tab to the. Heating it to 600 degrees will affect the metal. You can see the spots on the bowl wall where I left the material to fill in the damaged areas on the wall.

From temporary stick all the way up to welded forever. Utilize a grinder with angle a Dremel and or even sandpaper to totally eliminate JB Weld. Continue to wrap the pipe up to 6 inches from the area of the leak for a stronger seal.

When grinding it off it would be ideal if you try to wear a mask veil or respirator to try not to breathe in the residue since it very well may be perilous. Per JBs website info from last year grinding or filing or heat in excess of 600F is the only way to pull down hardened JB Weld. Might I also suggest experimenting on a piece of scrap to get a feel for the process.

It isnt recommended by plumbers and it doesnt work for plastic pipes but you can temporarily stop a. Removing JB Weld is actually pretty easy. Both adhere best to dry surfaces and are effective for blocking small leaks in copper and galvanized steel pipe.

Took a bit of cleaning couple of hours before I could make my first attempt at soldering a seam on a radiator. It bonds metal by making a Vacuum type seal as opposed to a covalent bond. Cut off desired amount of WaterWeld replacing unused portion back into tube for future use.

Small pin hole Leak in pipe.

Amazon Com J B Weld Fiberweld 2 Pipe Repair Cast 2x60 Inch High Strength Adhesive Fiberglass Wrap White 38260 Automotive

How To Remove Jb Weld The Complete Guide 2019

Removing Jb Weld Honda Cx 500 Forum

J B Weld Original Pro Size 10 Oz 8281 At Tractor Supply Co In 2021 Weld Twin Pack Epoxy

Waterweld Epoxy Putty J B Weld

Plastic Bonder Syringe Tan J B Weld

How Can I Remove Jb Weld Putty From Pants Fixit

J B Weld Clear Weld High Strength Epoxy 8 Oz Ace Hardware

J B Weld Clear Weld High Strength Epoxy Syringes 0 47 Oz Ace Hardware

J B Weld Original Twin Tubes 2 Pack Gray Epoxy Adhesive In The Epoxy Adhesives Department At Lowes Com

J B Weld Original Twin Tubes 2 Pack Gray Epoxy Adhesive In The Epoxy Adhesives Department At Lowes Com

How To Remove Jb Weld The Complete Guide 2019

How To Remove Jb Weld The Complete Guide 2019

How To Remove Jb Weld The Complete Guide 2019

How To Remove Jb Weld The Complete Guide 2019

How To Remove Old Jb Weld Using Torch J B Weld Removal Youtube

Post a Comment for "How To Remove Jb Weld From Pipe"